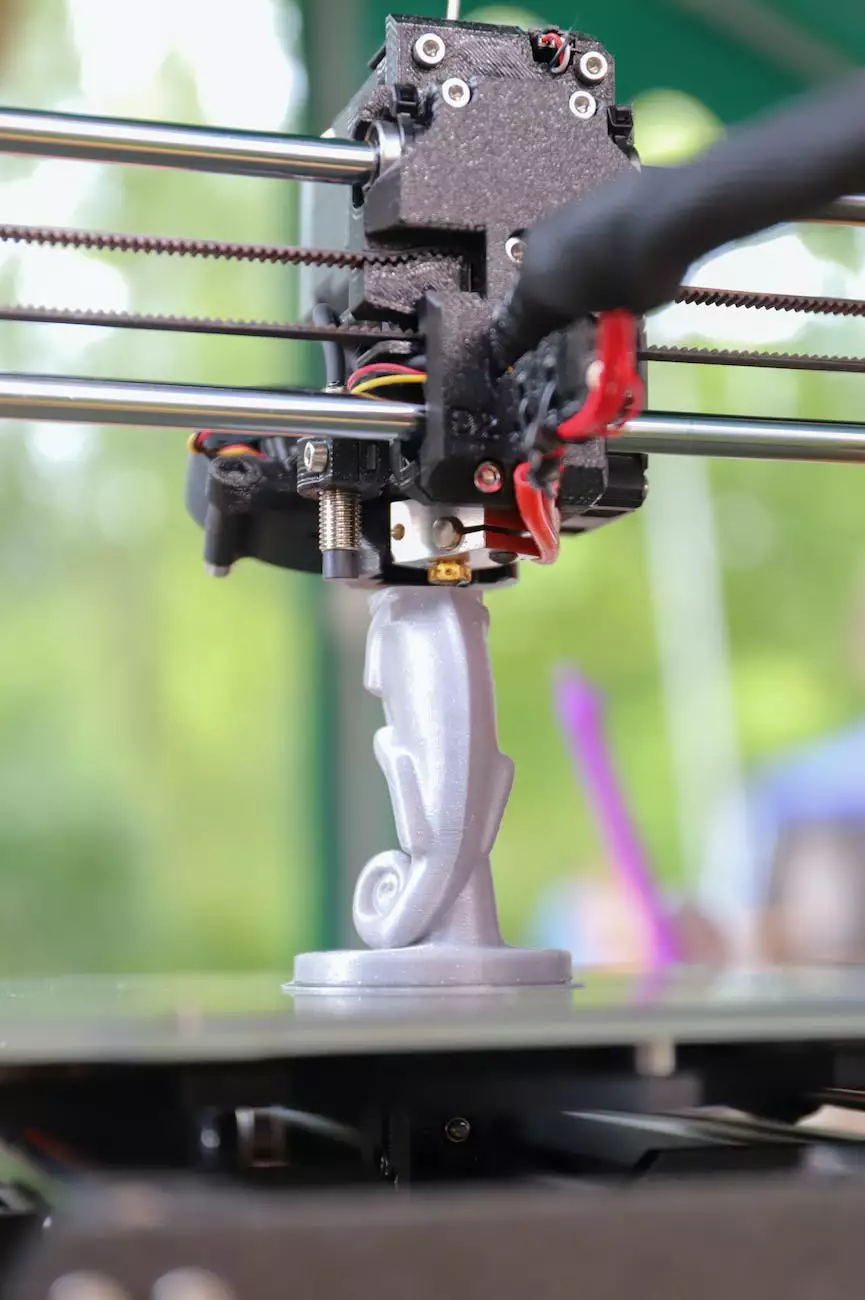

8 Ways 3D Printing Can Benefit Your Business

Blog

1. Rapid Prototyping

With 3D printing technology, Plastic Molding Pros can transform the prototyping process by allowing you to quickly and accurately create physical prototypes of your designs. This eliminates the need for expensive and time-consuming traditional prototyping methods, saving you both time and money.

2. Cost-Effective Production

By utilizing 3D printing, Plastic Molding Pros can significantly reduce production costs. Unlike traditional manufacturing methods that require costly molds and tooling, 3D printing allows for direct production from digital models. This eliminates the need for expensive tooling, reducing overhead costs associated with production.

3. Customization and Personalization

One of the key advantages of 3D printing is its ability to enable customization and personalization. Plastic Molding Pros can create unique products tailored to specific customer requirements, offering unparalleled flexibility in the manufacturing process. This opens up new opportunities for eCommerce businesses to meet the diverse needs and preferences of their customers.

4. Increased Efficiency

Integrating 3D printing into your manufacturing processes can greatly enhance efficiency. With traditional production methods, there are often multiple steps involved in creating a product. 3D printing consolidates these steps, allowing for streamlined production and reducing the potential for errors or delays. This increased efficiency translates into higher productivity and faster time to market.

5. Reduced Material Waste

3D printing technology enables Plastic Molding Pros to optimize material usage and reduce waste. Unlike traditional subtractive manufacturing processes, where excess material is often discarded, 3D printing builds objects layer by layer, using only the necessary amount of material. This not only minimizes waste but also helps in promoting sustainable manufacturing practices.

6. Complex Geometries and Design Freedom

With 3D printing, the limitations of traditional manufacturing methods no longer apply. Plastic Molding Pros can easily produce objects with complex geometries and intricate designs that would be challenging or impossible to create using conventional manufacturing techniques. This design freedom opens up a world of possibilities, allowing for the creation of innovative and unique products.

7. Just-in-Time Manufacturing

The flexibility of 3D printing allows Plastic Molding Pros to adopt a just-in-time manufacturing approach. With traditional manufacturing, maintaining large inventories can be costly and risky. However, 3D printing enables on-demand production, ensuring that products are manufactured and delivered only when needed. This reduces inventory costs and minimizes the risk of obsolete or unsold inventory.

8. Rapid Iteration and Design Optimization

With 3D printing's quick turnaround time, Plastic Molding Pros can rapidly iterate and optimize product designs. This agility allows for faster design iterations and the ability to make improvements based on real-world feedback. By incorporating 3D printing into the product development process, companies can accelerate innovation and stay ahead of the competition.

By harnessing the power of 3D printing, Plastic Molding Pros can seize a competitive advantage in the eCommerce and Shopping - Manufacture industry. From rapid prototyping to personalized production, the benefits of integrating 3D printing technology are undeniable. Stay at the forefront of innovation and revolutionize your business with Plastic Molding Pros.