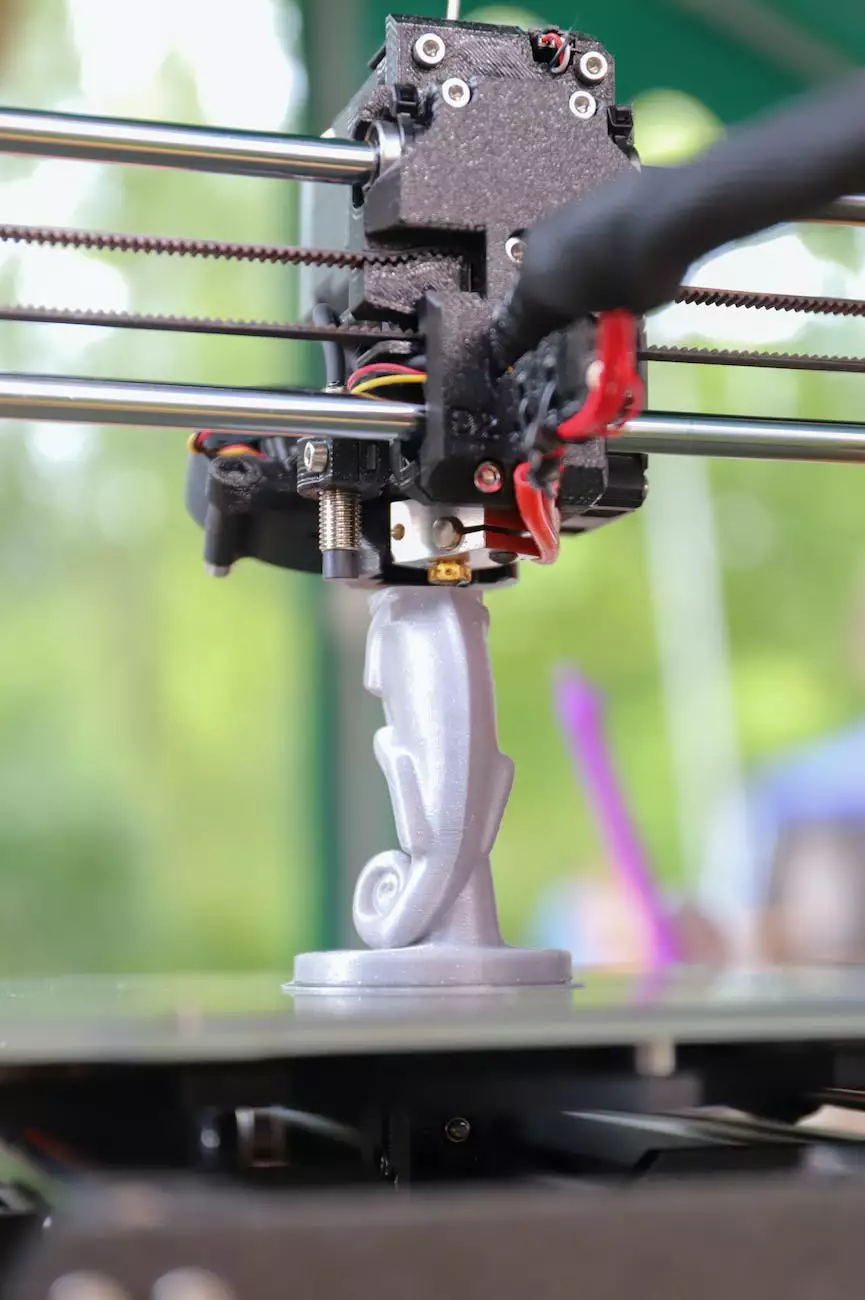

How 3D Printing Is Advancing The Cycling Industry

Blog

The Evolution of Manufacturing in the Cycling Industry

The cycling industry has always been at the forefront of innovation, constantly pushing the limits of what's possible. With the advent of 3D printing technology, the industry has witnessed a remarkable transformation in the way bicycles and related components are manufactured.

The Benefits of 3D Printing for Bike Components

3D printing, also known as additive manufacturing, allows for the creation of complex and customized bike components that were previously impossible to produce using traditional manufacturing methods. This technology offers:

- Lightweight and Strong Components: 3D printing enables the production of lightweight yet durable parts, resulting in improved performance and reduced overall weight of the bicycle.

- Customization: Cyclists can now personalize their bikes by designing and printing unique components tailored to their specific needs and preferences.

- Design Freedom: 3D printing eliminates the constraints of conventional manufacturing processes, enabling designers to unleash their creativity and explore innovative geometries.

- Reduced Waste: Additive manufacturing significantly reduces material waste compared to traditional methods, making it a more sustainable option for the cycling industry.

Revolutionizing Bike Helmets with 3D Printing

The cycling industry is no stranger to safety concerns, and one vital area where 3D printing is making a significant impact is in the production of bike helmets. With this technology:

- Custom Fit: Each cyclist has a unique head shape and size, and 3D printing allows for the creation of individualized and perfectly fitting helmets for enhanced safety and comfort.

- Improved Impact Protection: Additive manufacturing enables the integration of advanced cushioning systems and impact-absorbing materials in helmet designs, providing superior protection.

- Aerodynamic Designs: 3D printing allows for the creation of intricate and aerodynamic helmet shapes, reducing drag and improving overall performance.

- Ventilation and Cooling: By leveraging the design freedom offered by 3D printing, manufacturers can optimize airflow and ventilation systems within the helmet, enhancing rider comfort.

Exploring Innovations in Bike Frame Production

When it comes to bike frames, 3D printing offers numerous design possibilities and performance advantages:

- Optimized Strength-to-Weight Ratio: The ability to create complex lattice structures and consolidate several parts into a single component can significantly improve the overall strength-to-weight ratio of bike frames.

- Material Versatility: 3D printing allows for the use of diverse materials, such as carbon fiber, titanium, or high-strength plastics, enabling manufacturers to tailor frames for specific riding styles and preferences.

- Rapid Prototyping and Iteration: With additive manufacturing, designers can quickly develop and test new frame designs, iterating on concepts faster and facilitating product innovation.

The Future of 3D Printing in the Cycling Industry

As technology continues to advance, we can expect even more profound impacts from 3D printing on the cycling industry. Some future possibilities include:

- On-Demand Manufacturing: With 3D printers becoming more accessible, cyclists may have the ability to manufacture spare parts or customized components at home, reducing lead times and costs.

- Integration of Smart Technologies: 3D printing opens the door for the integration of sensors, connectivity features, and other smart technologies directly into bike components.

- Further Performance Enhancements: By leveraging advanced materials and design software, 3D printing has the potential to create even lighter, stronger, and more aerodynamic bike components.

Choose Plastic Molding Pros for Your 3D Printing Needs

If you're ready to embrace the future of manufacturing in the cycling industry, Plastic Molding Pros is your trusted partner. With our expertise in eCommerce & Shopping - Manufacture, we offer top-notch 3D printing services for a wide range of bike components and accessories. Contact us today to discuss your unique requirements and take advantage of the endless possibilities offered by 3D printing!