3D Scan Of A Wind Turbine Blade

Case Studies

The Future of Wind Turbine Blade Inspection

In the renewable energy industry, wind power plays a crucial role in sustainable energy production. Wind turbines have become larger and more complex over the years to capture higher wind energy conversion rates. However, maintaining and inspecting these massive structures presents challenges that require innovative solutions.

Introducing Plastic Molding Pros

Plastic Molding Pros, a trusted leader in the eCommerce & Shopping - Manufacture category, is proud to present a groundbreaking advancement in wind turbine blade inspection - the 3D scan of a wind turbine blade.

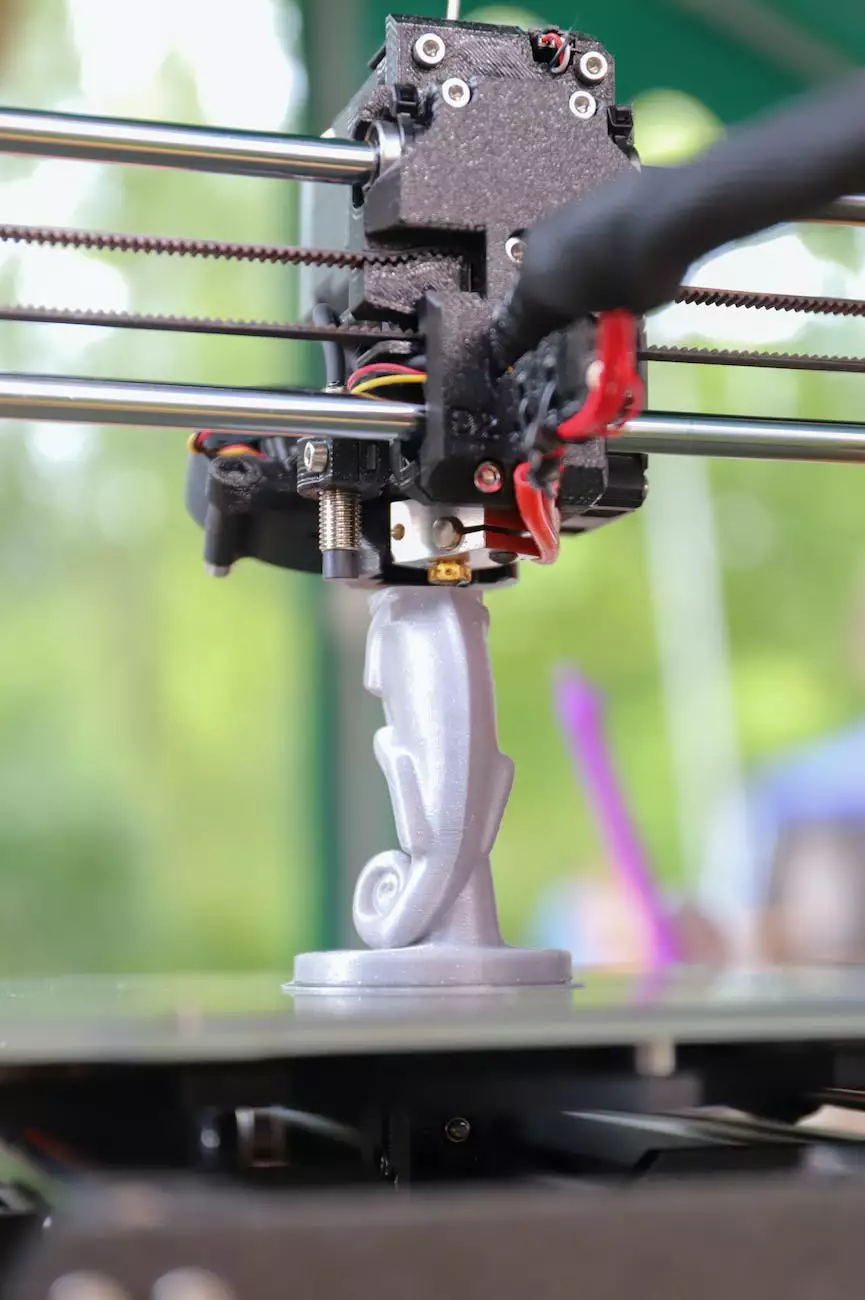

The Power of 3D Scanning Technology

Our 3D scanning technology combines precision, accuracy, and efficiency, revolutionizing the way wind turbine blades are inspected. By utilizing state-of-the-art scanning equipment, our skilled technicians can capture intricate details of each blade, enabling a comprehensive analysis of its structural integrity.

Unmatched Precision and Accuracy

With our 3D scan, every minute feature of a wind turbine blade is meticulously captured, providing engineers and maintenance experts with an unparalleled level of data accuracy. This advanced level of precision ensures a thorough understanding of potential vulnerabilities, such as cracks, deformations, or manufacturing defects.

Identifying Early Warning Signs

Early detection of blade issues is crucial to prevent catastrophic failures and ensure operational efficiency. Our 3D scanning process enables easy identification of hidden vulnerabilities that may otherwise go unnoticed by traditional inspection methods. By identifying these early warning signs, maintenance teams can proactively address concerns, minimizing downtime and maximizing turbine performance.

Streamlined Inspection Process

Traditional blade inspection methods often require time-consuming manual examinations or the use of expensive specialized equipment. Our 3D scanning process streamlines the inspection process by capturing detailed blade data rapidly and non-invasively. This efficiency not only reduces costs but also minimizes the downtime required for inspection, enabling wind farms to operate at full capacity for longer durations.

Enhanced Performance and Cost Savings

By leveraging the power of 3D scan technology, wind farm owners and operators can optimize maintenance strategies, extend blade lifecycles, and achieve substantial cost savings. The ability to identify issues early on and track their progression over time allows for efficient resource allocation and timely repairs, ultimately ensuring the highest level of turbine performance.

Trusted Expertise and Reliability

Plastic Molding Pros has established a reputation for delivering exceptional quality and reliability in the eCommerce & Shopping - Manufacture industry. Our team of experts possesses in-depth knowledge of wind turbine blade inspection requirements and has leveraged cutting-edge technology to provide superior services to our clients.

Contact Us Today

Are you ready to experience the future of wind turbine blade inspection? Contact us today to learn more about our 3D scan technology and how it can benefit your wind farm operations. Plastic Molding Pros - your trusted partner for innovative solutions in the renewable energy industry.

Disclaimer: Plastic Molding Pros provides advanced 3D scanning technology for wind turbine blade inspections. The information above is for informational purposes only and should not be considered as professional advice. Consult with a qualified engineer or expert for accurate and specific guidance regarding wind turbine blade maintenance and inspection.