3D Scanning Enhances Production Rate For Aftermarket Automotive Parts

Case Studies

Introduction

Welcome to Plastic Molding Pros, a renowned manufacturer in the eCommerce & Shopping industry. In this article, we will explore the pivotal role of 3D scanning technology in enhancing the production rate for aftermarket automotive parts.

The Need for Efficient Production in the Automotive Industry

The automotive industry is constantly striving to meet the demands of customers who seek reliable, high-quality aftermarket parts. Traditionally, the production process has proven to be time-consuming and costly. However, with the advent of 3D scanning, manufacturers are now able to streamline their production processes.

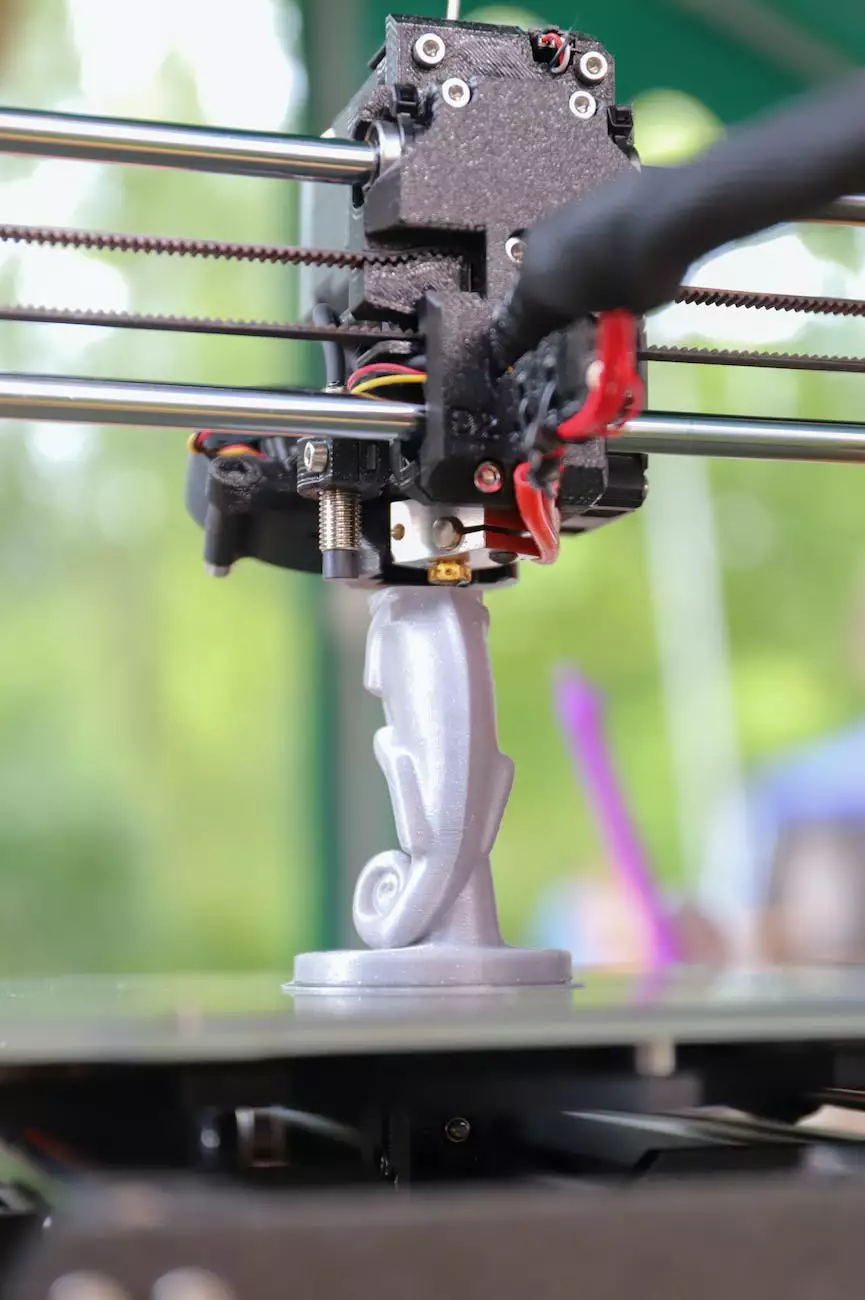

What is 3D Scanning?

3D scanning is a cutting-edge technology that captures the precise geometric shape and dimensions of a physical object. By utilizing lasers, cameras, and advanced software algorithms, 3D scanners create detailed digital representations of objects in a matter of seconds.

Benefits of 3D Scanning in the Automotive Industry

3D scanning offers numerous advantages for aftermarket automotive part manufacturers, including:

- Accuracy: 3D scanning provides highly accurate measurements, ensuring precise reproduction of parts.

- Time Efficiency: Compared to traditional measuring methods, 3D scanning significantly reduces the time required for measurements, resulting in faster production rates.

- Cost Reduction: By streamlining the production process, 3D scanning helps reduce costs associated with manual measurements and revisions.

- Quality Assurance: 3D scanning minimizes human errors and ensures consistent quality in every aftermarket part produced.

- Reverse Engineering: 3D scanning allows for the easy creation of digital models from existing parts, facilitating the production of identical copies or modifications.

Applications of 3D Scanning in the Automotive Industry

3D scanning finds extensive use in various aspects of the automotive manufacturing process, including:

Design and Prototyping

By scanning existing parts or prototypes, manufacturers can create accurate three-dimensional models that serve as a basis for design and further optimization. This expedites the product development cycle and allows for rapid refinement.

Quality Control

3D scanning enables thorough quality control inspections by comparing scanned parts against the original design. This ensures that each aftermarket part meets strict quality standards.

Tooling

Through precise measurements and capturing complex forms, 3D scanning aids in the production of custom tooling for automotive part manufacturing. This process enhances overall efficiency and reduces time-to-market.

Legacy Part Reproduction

With 3D scanning, manufacturers can reproduce discontinued or hard-to-find parts by digitally capturing existing components. This saves considerable time and expense compared to traditional methods that involve manual measurements or reverse engineering.

Plastic Molding Pros: Your 3D Scanning Partner

As a leading eCommerce & Shopping manufacturer, Plastic Molding Pros is committed to leveraging cutting-edge technologies like 3D scanning to deliver exceptional aftermarket automotive parts to our clients. Our state-of-the-art facilities and expert team ensure the highest standards of quality and efficiency.

Conclusion

The integration of 3D scanning technology in the automotive industry has revolutionized the production rate for aftermarket parts. Plastic Molding Pros is at the forefront of utilizing this technology to meet the demands of customers seeking top-quality automotive components. With our dedication to innovation, we continue to push the boundaries of what's possible in the realm of aftermarket automotive part manufacturing.