Deep Dive Into The World Of 3D Scanning And 3D

Blog

Introduction

Welcome to Plastic Molding Pros' comprehensive guide on 3D scanning and 3D measurement technology. In this article, we will explore the exciting world of 3D scanning and its applications in the realm of plastic molding.

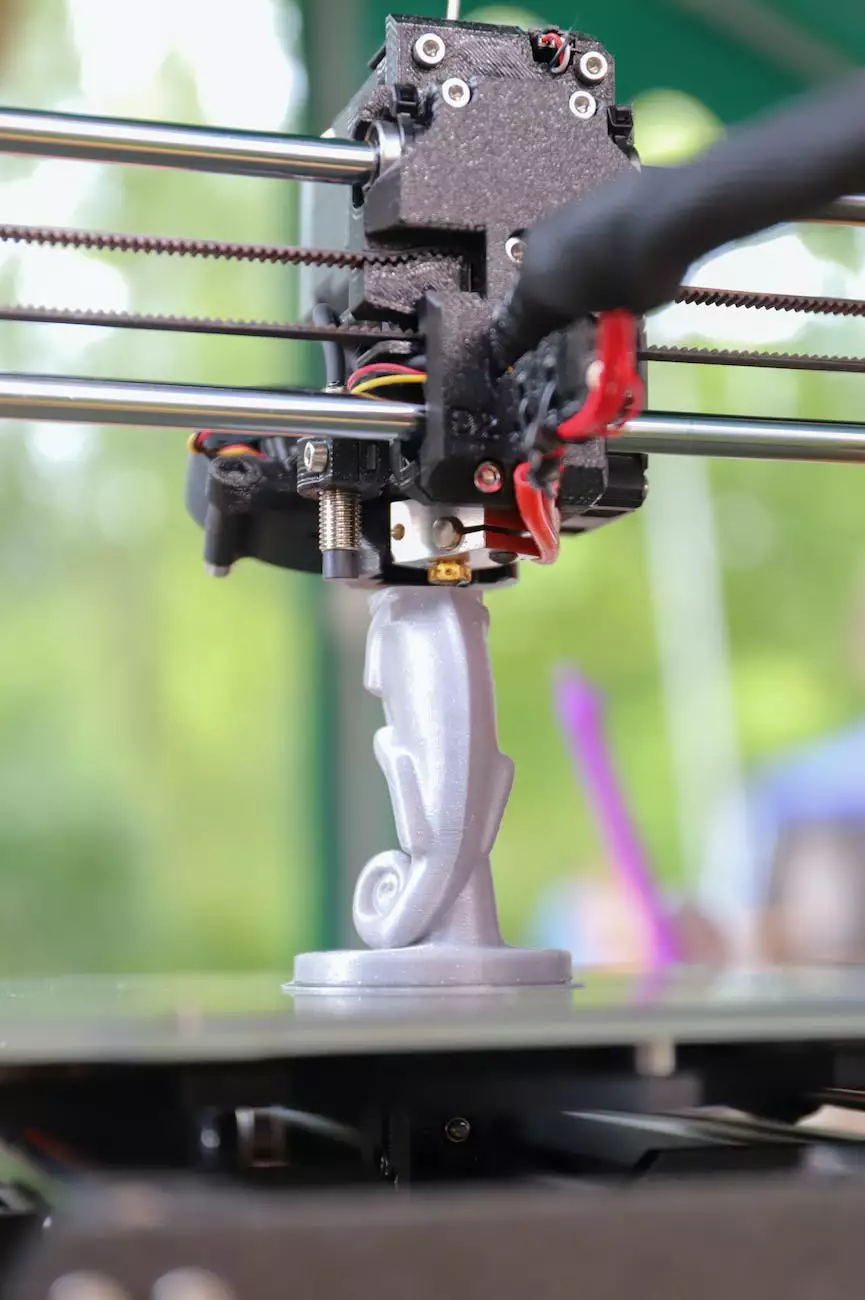

What is 3D Scanning?

3D scanning is the process of capturing accurate, three-dimensional data of physical objects or environments using specialized equipment. By utilizing various technologies such as laser scanners or structured light systems, 3D scanners create digital representations of real-world objects with high precision.

Applications of 3D Scanning in Plastic Molding

3D scanning plays a crucial role in the field of plastic molding. Here are some key applications where this technology can enhance your eCommerce & Shopping - Manufacture business:

Quality Assurance and Inspection

With 3D scanning, you can perform comprehensive quality assurance and inspection processes. By scanning plastic molded components, you can compare the acquired data with the original design specifications, ensuring the dimensional accuracy and identifying any deviations or defects.

Reverse Engineering

Reverse engineering is simplified with 3D scanning technology. It allows you to create a digital replica of an existing physical part, which can then be used as a reference for redesign or reproduction. This opens up opportunities for product improvement and cost-effective manufacturing.

Design Verification

By utilizing 3D scanning, you can verify the integrity of your plastic molding designs. With highly detailed scans, you can analyze how the design translates into physical form, identifying potential issues or areas of improvement before initiating production.

Prototyping and Mold Making

3D scanning can expedite the prototyping and mold-making process. By capturing the exact shape and dimensions of a physical object, you can create accurate 3D models for mold development. This ensures precision in manufacturing and reduces the risk of iterations and costly errors.

Choosing the Right 3D Scanning Technology

With a plethora of 3D scanning technologies available, it's essential to choose the right one for your specific plastic molding requirements. Consider the following factors:

Accuracy and Resolution

Ensure that the 3D scanning technology you choose offers the necessary level of accuracy and resolution required for your plastic molding applications. Higher accuracy allows for tighter tolerances, resulting in better quality parts.

Scanning Speed

Take into account the scanning speed of the technology. Faster scanning speeds can significantly reduce the time required for capturing complex geometries, enhancing efficiency and productivity.

Material Compatibility

Verify that the 3D scanning technology is compatible with the materials commonly used in plastic molding. Different scanners have varying capabilities when it comes to scanning different types of plastics, so thorough research is essential.

The Future of 3D Scanning in Plastic Molding

As technology continues to advance, so does the potential of 3D scanning in the realm of plastic molding. Some exciting developments include:

Real-time Scanning

Real-time 3D scanning allows for instant feedback during the design and manufacturing phases, reducing time-to-market and speeding up the overall production process.

Integration with Artificial Intelligence

Artificial intelligence algorithms can be integrated with 3D scanning systems to automate processes such as quality control, defect detection, and part recognition. This results in enhanced efficiency and accuracy.

Portable 3D Scanning Solutions

Advancements have led to the development of portable 3D scanning solutions, allowing for on-site scanning and immediate data capture. This can be particularly advantageous for field inspections and quality assessments.

Conclusion

In conclusion, 3D scanning and 3D measurement technology has become an indispensable tool in the world of plastic molding. From quality assurance to design verification and mold making, its applications are vast and varied. Make sure to choose the right 3D scanning technology that aligns with your specific requirements, and unlock the full potential of this revolutionary technology for your eCommerce & Shopping - Manufacture business.

Plastic Molding Pros - eCommerce & Shopping - Manufacture