Understanding Diesel Engine Cylinder Heads: A Comprehensive Guide

The diesel engine cylinder head is a critical component that plays a significant role in the performance and efficiency of diesel engines. Understanding its structure, functions, and maintenance can help both vehicle owners and mechanics enhance engine performance and longevity. This article delves deep into the world of diesel engine cylinder heads, exploring their design, importance, common issues, and the best practices for upkeep.

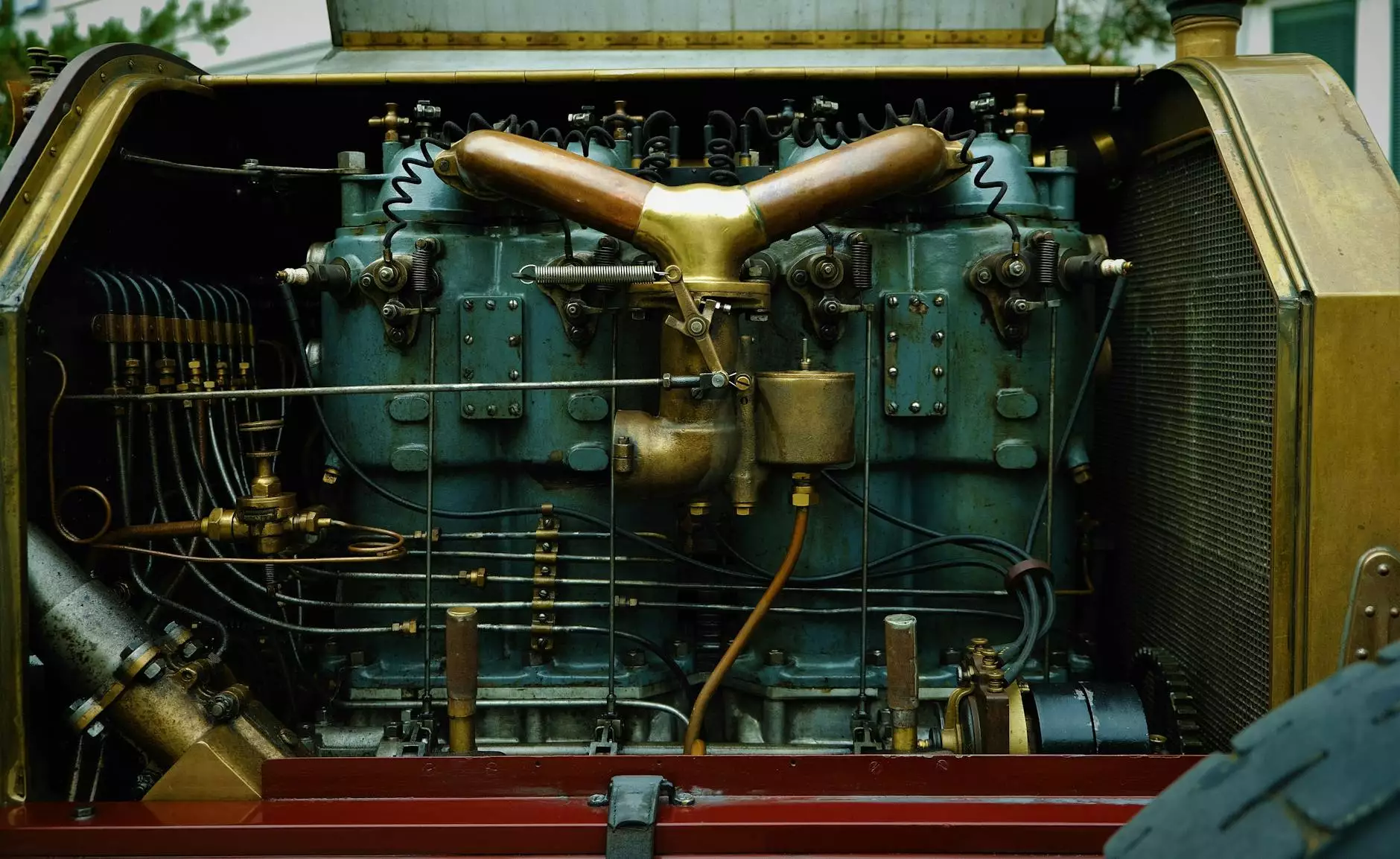

What is a Diesel Engine Cylinder Head?

The diesel engine cylinder head is an integral part of an internal combustion engine. It forms the upper part of the combustion chamber, sealing the cylinders and enabling the combustion process to take place efficiently. The cylinder head is equipped with vital components such as valves, spark plugs, and injectors, which are crucial for the engine's operation.

Key Functions of the Cylinder Head

- Sealing the Combustion Chamber: The cylinder head forms a tight seal over each cylinder, preventing the escape of gases during the combustion cycle.

- Facilitating Air and Fuel Flow: Equipped with intake and exhaust valves, the cylinder head regulates the airflow into and out of the cylinder, allowing efficient combustion.

- Heat Dissipation: The cylinder head is designed to dissipate heat produced during combustion, helping to maintain optimal engine temperatures.

- Supporting Engine Components: Many essential components, including fuel injectors and rocker arms, are mounted on the cylinder head, making it a fundamental part of the engine assembly.

Components of a Diesel Engine Cylinder Head

To better understand the functionalities of the cylinder head, it is important to recognize its various components. Here are the primary elements found in a diesel engine cylinder head:

Valves

Valves are critical to the functioning of the cylinder head. They control the intake of air and the exhaust of combustion gases. In diesel engines, these are typically intake valves and exhaust valves, each designed to operate under high pressure and temperature.

Fuel Injectors

Fuel injectors are responsible for injecting fuel into the combustion chamber. In a diesel engine, the fuel is injected into the cylinder at high pressure, allowing for efficient combustion.

CAMshaft and Tappets

The CAMshaft rotates to open and close the valves, while tappets transfer this motion from the CAMshaft to the valves. These components play a vital role in the timing of the combustion process.

Common Issues with Diesel Engine Cylinder Heads

Diesel engine cylinder heads, while robust, can be prone to several issues due to various factors such as overheating, corrosion, and wear. Here are some common problems associated with cylinder heads:

- Cracking: Overheating can lead to cracks in the cylinder head. This is particularly problematic as it can lead to coolant leaks and loss of compression.

- Warping: Excessive heat can also warp the cylinder head, leading to improper sealing and loss of engine efficiency.

- Valve Wear: Continuous operation can cause valve surfaces to wear down, affecting their ability to close properly and consequently reducing engine performance.

- Gasket Failure: The head gasket, which seals the head to the engine block, can fail due to heat and pressure, leading to coolant and oil leaks.

Maintenance Tips for Diesel Engine Cylinder Heads

Regular maintenance of the cylinder head can greatly enhance the performance and lifespan of a diesel engine. Below are some essential maintenance tips:

Regular Inspections

Routine inspections can help identify early signs of wear or damage. Look for signs of leaking fluids, especially around the head gasket, and monitor engine temperature closely.

Ensure Proper Cooling

Maintaining the cooling system is vital for preventing overheating. Regularly check the coolant levels and ensure the radiator and water pump are functioning properly.

Quality Fuel and Oil

Using high-quality fuel and oil can prevent deposits from forming in the combustion chamber and on the valves, leading to smoother operation and prolonged service life.

Professional Servicing

Having your engine serviced by a professional can ensure that the cylinder head and related components are in optimal condition. This includes proper valve adjustments and gasket replacements when necessary.

Enhancing Diesel Engine Performance Through Quality Parts

The performance of a diesel engine can significantly improve with high-quality parts, including the diesel engine cylinder head. Investing in quality aftermarket or OEM parts can lead to better efficiency, reduced fuel consumption, and enhanced power output. At client-diesel.com, we provide a comprehensive range of diesel engine parts that meet the highest industry standards.

Why Choose Quality Diesel Engine Parts?

Choosing quality parts for your diesel engine can provide several advantages:

- Improved Engine Performance: Quality parts like cylinder heads are designed for optimal performance, which can translate to better horsepower and torque.

- Reliability: Superior parts offer greater reliability, reducing the frequency of repairs and associated costs.

- Longevity: High-quality components typically have a longer lifespan, contributing to reduced maintenance needs over time.

- Better Resale Value: Vehicles equipped with quality parts often maintain a higher resale value due to their enhanced performance and reliability.

Conclusion

Understanding the functionality and importance of the diesel engine cylinder head is crucial for anyone involved in the maintenance or operation of diesel engines. Regular maintenance, quality components, and professional servicing can significantly enhance engine performance and longevity. Make sure to visit client-diesel.com for a range of reliable diesel engine parts to optimize your vehicle's performance.