Understanding Water Pumps with Diesel Engines

In the world of industrial machinery, winter pumps with diesel engines stand out as a critical piece of equipment. They serve numerous purposes across various applications, including agriculture, construction, and mining. This article delves into the intricacies of water pumps powered by diesel engines, highlighting their importance, functionality, and advantages.

What is a Water Pump with Diesel Engine?

A water pump with a diesel engine is a mechanical device designed to move water from one location to another using the power generated by a diesel engine. These pumps are particularly known for their durability, efficiency, and ability to operate in remote areas where electrical power may not be available. The synergy between the water pump and the diesel engine creates a robust system capable of handling large volumes of water efficiently.

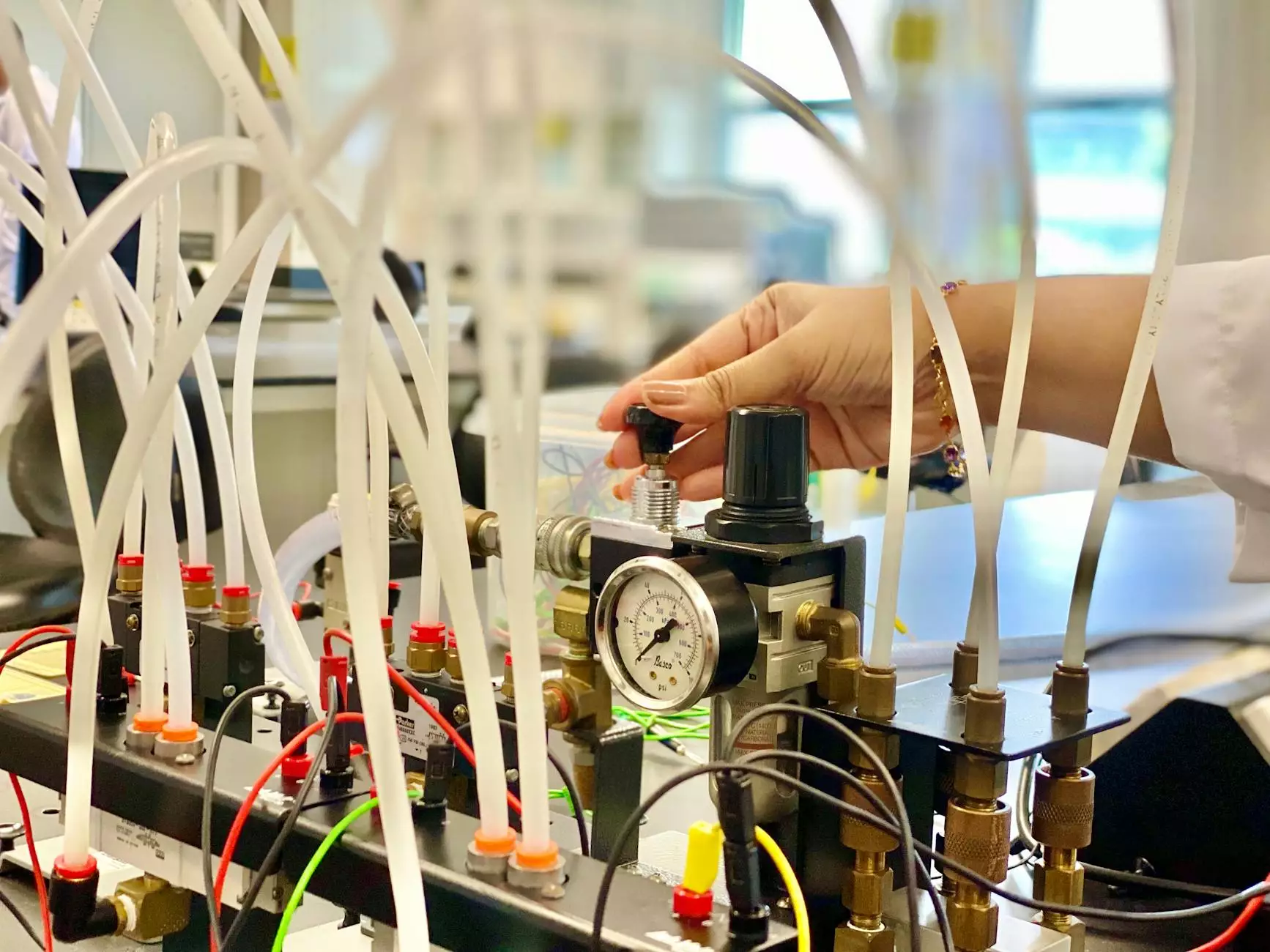

Key Components of Diesel Water Pumps

Understanding the components of a water pump with a diesel engine is essential for appreciating its operation. The main parts include:

- Diesel Engine: The power source that drives the pump, providing the necessary torque and speed.

- Pump Assembly: This includes the impeller, volute, and casing that work together to move water.

- Fuel System: Comprising the fuel tank, injection pump, and filters, this system ensures the engine receives clean diesel fuel.

- Cooling System: Necessary for maintaining optimal engine temperatures to prevent overheating.

- Exhaust System: Channels exhaust gases away from the engine for better performance and safety.

The Working Principle

The operational mechanism of a water pump with diesel engine involves several steps:

- Activation: The diesel engine starts, fueled by the diesel fuel from the tank.

- Power Generation: As the engine runs, it generates rotational energy, which is transferred to the pump.

- Water Movement: The impeller within the pump creates centrifugal force, which moves water from the inlet to the outlet.

- Discharge: The water exits the pump at high pressure, ready to be directed to where it’s needed.

Advantages of Using Diesel Engine Water Pumps

Water pumps with diesel engines offer numerous advantages that make them indispensable in various sectors:

1. Durability and Longevity

Diesel engines are built for endurance and resilience. They are designed to operate in demanding conditions, making them ideal for applications in construction sites and agricultural fields.

2. High Efficiency

Compared to other types of pumps, diesel engine water pumps demonstrate superior efficiency, particularly in high-pressure applications. Their ability to handle large quantities of water means they can perform heavy lifting without straining the system.

3. Portability

Many diesel-powered pumps are portable and can be moved easily to different sites. This flexibility ensures that water can be sourced from various points without the need for fixed installations.

4. Fuel Availability

Diesel fuel is usually more accessible than gasoline in many regions, especially in remote areas. This accessibility makes diesel water pumps a practical choice for agricultural and construction applications.

5. Lower Operating Costs

Diesel engines tend to have a lower cost of operation over time compared to gasoline engines. They consume less fuel while providing more power, leading to significant savings in long-term operational costs.

Applications of Water Pumps with Diesel Engines

Water pumps powered by diesel engines are versatile and cater to numerous applications:

Agricultural Irrigation

Farmers utilize diesel water pumps to irrigate fields, ensuring crops receive adequate water for growth. The ability to operate in off-grid areas is especially beneficial for rural farming.

Construction Sites

In the construction industry, these pumps are essential for dewatering excavated sites and managing water during heavy rainfall. They help maintain a dry work environment, which is critical for project timelines and safety.

Mining Operations

In mining, water pumps are employed to remove excess water from mines, ensuring safe working conditions. Diesel-powered pumps can handle the brunt of high water levels in these operations.

Flood Control Systems

During floods, diesel water pumps are deployed for rapid water removal to protect properties and infrastructure. Their swift mobilization and high capacity make them crucial in emergency situations.

Choosing the Right Diesel Engine Water Pump

When selecting a water pump with a diesel engine, consider the following factors:

1. Flow Rate

The flow rate needed for your specific application. Pumps are available in various flow rates; selecting one that meets your requirements is essential.

2. Head Pressure

Understand the vertical distance the water needs to be moved. Higher head pressure will require more robust diesel engines and pump models.

3. Portability

If you plan to move the pump frequently, consider its size and weight. Look for models designed for easy transport without compromising performance.

4. Fuel Efficiency

Evaluate the engine's fuel efficiency, as this impacts your overall operational costs. More economical engines will save money in the long run.

5. Manufacturer Reputation

Research manufacturers, like client-diesel.com, known for quality diesel engine parts and reliable service. A reputable supplier will ensure that you receive high-quality products and support.

Maintenance Tips for Diesel Water Pumps

Maintaining your water pump with a diesel engine is crucial for long-term performance:

1. Regular Inspections

Conduct routine inspections on the engine and pump components for wear and tear, ensuring early detection of potential issues.

2. Change Oil and Filters

Frequent oil changes and filter replacements are necessary for maintaining engine efficiency and preventing failure.

3. Clean Fuel System

Keep the fuel system clean to prevent clogging and ensure optimal engine performance.

4. Monitor Cooling System

Regularly check the cooling system to avoid overheating, which can lead to significant engine damage.

5. Store Properly

If not in use, store the pump properly in a dry environment to prevent corrosion and damage from elements.

Conclusion

In conclusion, winter pumps with diesel engines are an essential investment for numerous industrial and agricultural applications. Their robust design, efficiency, and adaptability make them a top choice for water movement solutions. Understanding their components, advantages, applications, and maintenance requirements empowers businesses and individuals to maximize their use. By selecting quality pumps and working with reliable suppliers like client-diesel.com, you can ensure longevity and efficiency in your operations.