3D Printing: Revolutionizing the Street Sweeping Vehicle Industry

Introduction

As technology continues to evolve, one industry that has significantly benefited from these advancements is the street sweeping vehicle industry. With the emergence of 3D printing, sweeping vehicle manufacturers like Ceksan Sweepers have been able to revolutionize the design, production, and effectiveness of their products, resulting in increased efficiency and improved quality. In this article, we will explore the various ways in which 3D printing has transformed the street sweeping vehicle industry and how Ceksan Sweepers has leveraged this technology to stay ahead of the competition.

The Power of 3D Printing

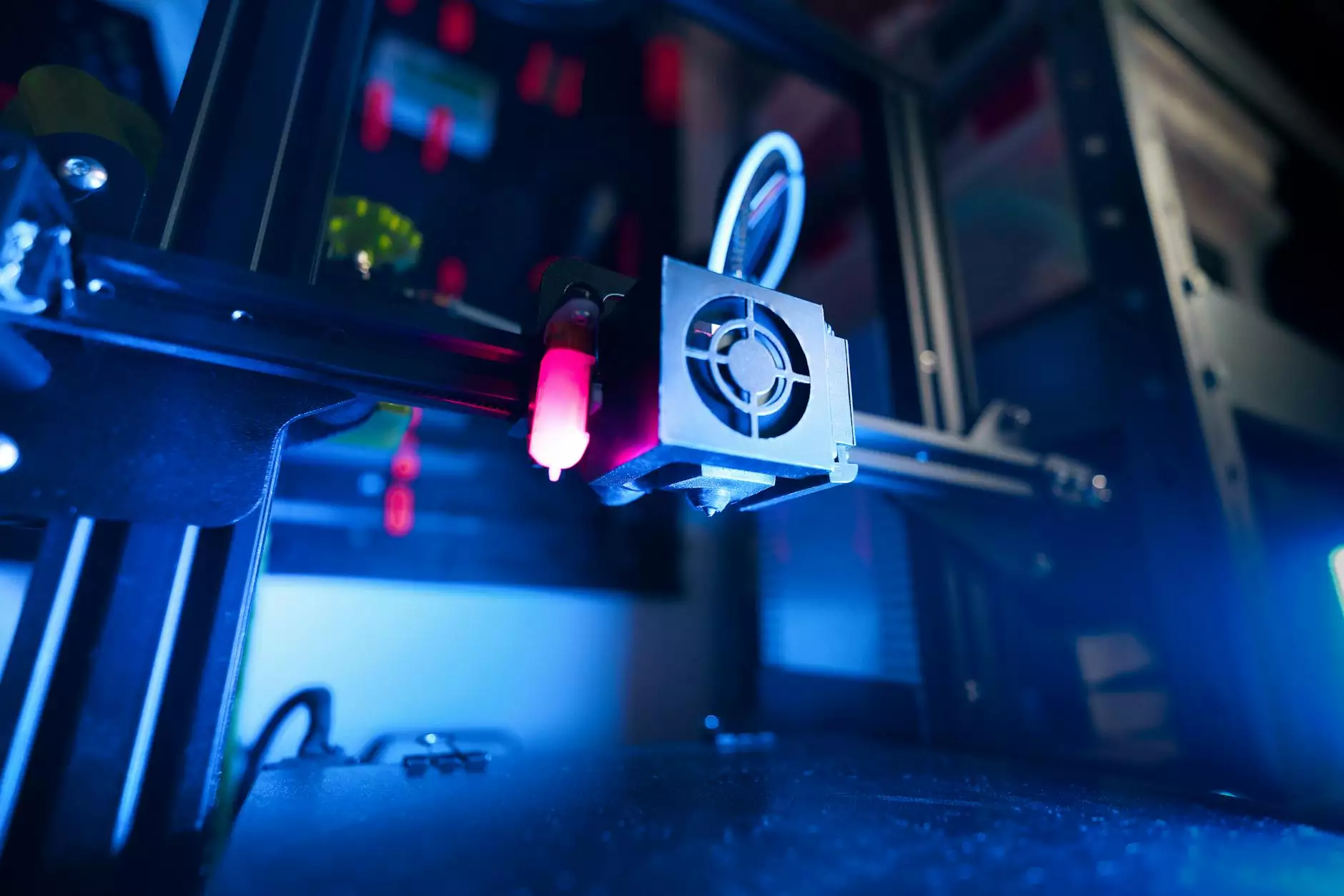

3D printing, also known as additive manufacturing, is a groundbreaking technology that allows for the creation of three-dimensional objects using a layer-by-layer approach. Unlike traditional manufacturing methods, which often involve extensive tooling, time-consuming processes, and design limitations, 3D printing offers unparalleled flexibility and customization options.

For the street sweeping vehicle industry, this technology has proven to be a game-changer. Manufacturers like Ceksan Sweepers can now create highly intricate and complex components with ease. This not only improves the functionality of the vehicles but also enhances their overall performance and durability.

Enhancing Vehicle Design

With 3D printing, Ceksan Sweepers has been able to push the boundaries of vehicle design. By utilizing this technology, their engineers can create prototypes and test different concepts in a fraction of the time of traditional methods. This iterative design process allows for faster product development and more efficient problem-solving.

Furthermore, 3D printing enables the production of lightweight yet robust components. By using advanced materials, such as carbon fiber-reinforced polymers, Ceksan Sweepers can design vehicles that are not only more efficient in terms of fuel consumption but also offer improved maneuverability and reduced environmental impact.

Optimizing Production Processes

Traditionally, manufacturing street sweeping vehicles involved multiple steps, including mold making, casting, and assembly. These processes were both time-consuming and costly. However, with the integration of 3D printing, Ceksan Sweepers has streamlined their production processes, resulting in significant time and cost savings.

By employing 3D printing, complex components can be produced in-house, eliminating the need for outsourcing or tooling. This not only reduces lead times but also ensures better quality control. Additionally, the ability to print components on-demand enables Ceksan Sweepers to respond quickly to customer demands and adapt to market changes more effectively.

Advancements in Street Sweeping Technology

Thanks to 3D printing, the street sweeping vehicle industry has witnessed remarkable advancements in terms of technology and functionality. Ceksan Sweepers has capitalized on this technology to introduce innovative features that significantly enhance performance and efficiency.

One area where 3D printing has had a profound impact is in the development of precision cleaning brushes. By using this technology, Ceksan Sweepers has been able to create brushes with intricate bristle patterns that can effectively capture and remove debris from various surfaces. This cutting-edge design ensures a more thorough and efficient cleaning process, ultimately saving time and resources.

Additionally, 3D printing has allowed for the customization of sweeping vehicle attachments. Ceksan Sweepers can now tailor attachments for specific cleaning environments and adapt to the unique needs of their clients. This level of customization ensures optimal performance, ultimately improving customer satisfaction.

The Future of Street Sweeping Vehicles

With ongoing advancements in 3D printing technology, the future of street sweeping vehicles looks promising. As materials become more advanced and the printing process becomes faster and more cost-effective, Ceksan Sweepers and other manufacturers will continue to push the boundaries of innovation within the industry.

Furthermore, as sustainability becomes an increasingly important aspect in every industry, 3D printing allows for greater use of recycled and eco-friendly materials. This means that future street sweeping vehicles can be more environmentally friendly without compromising performance.

Conclusion

It is evident that 3D printing has transformed the street sweeping vehicle industry. With its ability to enhance design, optimize production processes, and introduce groundbreaking technology, manufacturers like Ceksan Sweepers have gained a competitive edge in an ever-evolving market.

As this technology continues to evolve, we can expect even more advancements in the near future. The combination of customization, efficiency, and improved environmental sustainability makes 3D printing a game-changer for the street sweeping vehicle industry, and Ceksan Sweepers stands at the forefront of this revolution.